ZDGT1015 Industrial Robot

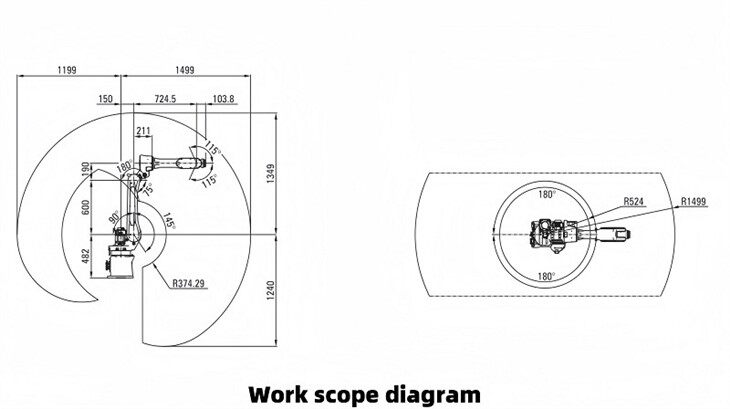

Introduction:The Polish Robot mainly composed of industrial robot body, grinding machine, force control equipment, gripper and other peripheral equipment. Through system integration, the hardware and software of the robot and peripheral equipment are connected and coordinated by the general control cabinet. Through teaching and offline programming, automatic grinding and deburring of the robot can be realized. Polish the base and actuator of the robot, including arms, wrists and hands. The arm length is 1499mm and the load is 10kg.

There are two main ways of robot grinding: one is to grip the grinding tool through the robot end effector, actively contact the workpiece, the workpiece is relatively fixed, called the tool active grinding robot; The other is the robot end effector holding the workpiece, through the workpiece close contact with the deburring machine equipment, the machine equipment is relatively fixed, called the workpiece active grinding robot.

|

Robot model |

Freedom |

Load |

Arm length |

Repeatability |

|

ZDGT1015 |

6 |

10kg |

1499mm |

±0.08mm |

Field

It is used for surface grinding of workpiece, edge and corner deburring, weld grinding, inner cavity and inner hole deburring, hole and thread machining, etc. It is mainly used for grinding of sanitary ware industry, I industry, auto parts, industrial parts, medical equipment, civil products and so on.

Main Advantages

1. Improve productivity, can be 24 hours a day continuous production, can work in harmful environment for a long time.

2. Accuracy and repeatability: ± 0.08mm accuracy for positioning and manipulation, so as to ensure the accuracy in the work

3. Automation and efficiency: automatic grinding instead of manual, improve production efficiency.

4. Wide application: Industrial grinding robots often need to adapt to a range of workpiece forms, sizes and materials. Robotic end effectors typically have flexible and mobile features that allow them to adapt to a variety of workpiece surfaces and change grinding forces as needed.

5. Sensing and feedback: Some complex industrial robots include sensors and vision systems that can detect the shape and roughness of the workpiece surface. The robot can change its strategy in real time during the polishing process, obtaining the desired surface quality by using this feedback data for adaptive control.

6. Safety: Safety is critical as polishing operations may require high-speed rotation of equipment and robotic moving parts. To keep humans safe while operating, industrial robots often include safety features, including shields, collision detection, and emergency stop buttons.

Service

1. The warranty period is one year,.

2. After-sales service 24 hours online answer your questions, and summarize the feedback to the technical staff.

3. Our company's engineers can provide overseas after-sales service.