High-Speed Slant Bed CNC Lathe: The Ideal Choice for Precision Machining

In modern manufacturing, the High Speed Slant Bed CNC Lathe has become the preferred equipment for processing small to medium-sized shafts and disc-type components. Known for its high precision, efficiency, and versatility, this machine meets the demanding needs of today's metalworking industry.

Key Features

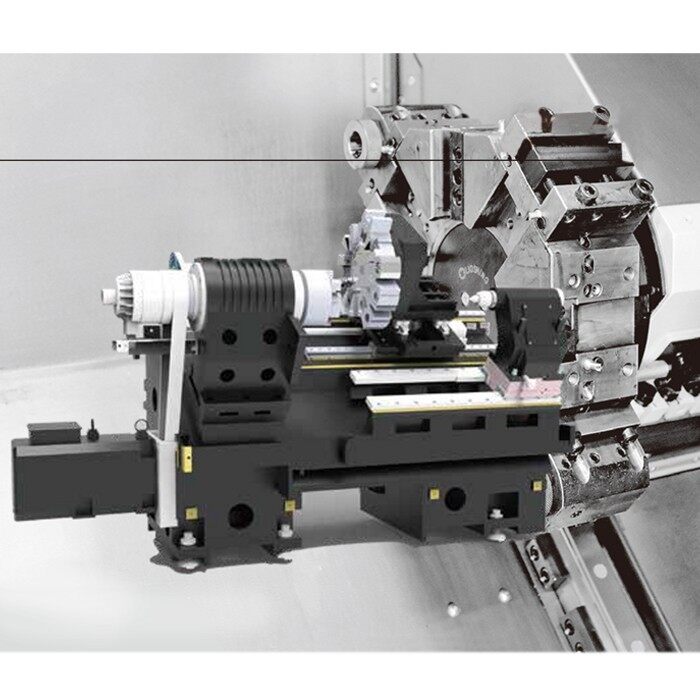

1. Taiwan Roller-Type Linear Guideways: Deliver exceptional rigidity and stability, ensuring high machining accuracy over long-term operation.

2. High-Speed, High-Precision, High-Rigidity Spindle Unit: Engineered for fast and stable cutting, this spindle significantly improves production efficiency.

3. Embedded Lubrication System: Ensures automatic and consistent lubrication, extending the service life of key components and reducing maintenance requirements.

4. High-Rigidity Integral Slant Bed Structure: Designed for optimal chip evacuation and structural stiffness, making it suitable for heavy-duty machining tasks.

5. Compatibility with Various CNC Systems: Supports mainstream controllers like FANUC, Siemens, and GSK, offering intuitive operation and flexible programming.

Lathe model parameters

Applications

This Precision slant bed CNC lathe is widely used in industries such as plumbing fixtures, valves, electrical components, instruments, automotive parts, motorcycles, and bearings. With its high-efficiency cutting capability, it stands out as a reliable High-speed CNC turning machine for the precision machining of various metal components.

Advantages

1. Optimized Structure for Superior Stability

The machine adopts an integrated slant bed design, providing excellent rigidity and vibration resistance. This structure ensures stable machining performance, improves chip removal efficiency, and guarantees consistent part quality during extended operation.

2. High-Speed Spindle for Efficient Production

Equipped with a high-performance spindle unit capable of high-speed rotation and stable cutting, the machine is ideal for processing aluminum, steel, and other common metals. It significantly reduces cycle time and boosts production efficiency.

3. Precision Linear Guideways for Lasting Accuracy

Using Taiwan-sourced roller-type linear guideways, the lathe maintains high positioning and repeatability accuracy over long periods. Its low friction and wear resistance make it a reliable choice for high-precision part machining.

4. Multi-Functional Capability for Complex Machining

This high-speed slant-bed Bed CNC Lathe supports turning, threading, taper machining, and internal/external contour shaping. It's especially well-suited for small and medium-sized shafts and disc parts, making it a preferred solution in the automotive, valve, and instrumentation industries.

5. Automatic Lubrication for Reduced Maintenance

An embedded lubrication system ensures key components are consistently lubricated, reducing wear and minimizing the need for frequent manual maintenance. This improves machine uptime and overall cost-efficiency.

6. Compatible with Major CNC Systems

The lathe supports a range of mainstream CNC controllers, including FANUC, Siemens, and GSK. Its intuitive interface and multi-language support allow for quick setup, easy operation, and flexible programming to meet varied production demands.

Our Services

1】One-Year Warranty:

Enjoy a one-year warranty period that reflects our commitment to Reliability and Stability, ensuring that each machine meets the highest standards in performance and longevity.

2】24/7 Professional Support:

Our Professional After-Sales Service team is available online 24 hours a day. Leveraging Digital Control Systems and Online Monitoring and Diagnostics, we promptly address your inquiries and deliver detailed feedback to our technical staff.

3】Global Engineering Assistance:

Our skilled engineers provide comprehensive overseas after-sales service, ensuring that our Customized Solutions support Smart Manufacturing practices globally.

4】Local Technical Service Center:

We are actively preparing a local technical service center to further enhance our support network, reinforcing our commitment to Professional After-Sales Service and the overall Reliability and Stability of our products.

By integrating advanced technologies and tailored support, we deliver efficient, high-quality service that meets the evolving needs of modern manufacturing.

FQA

Q: 1. What are the contents of the after-sales service for machine tools?

Q: 2. Can the machine be customized?